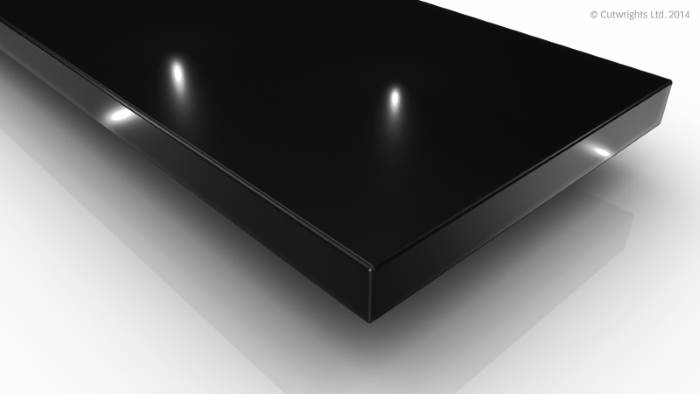

Offering a competitive price and exceptional quality comes as standard when using Cutwrights. Current trends of high gloss boards, matt finishes and deep textured melamine boards are just a few of the surfaces our edgebanders are faced with daily. You can be assured our machines are more than capable of applying over fourteen different edge types to a finish that will exceed your expectations.

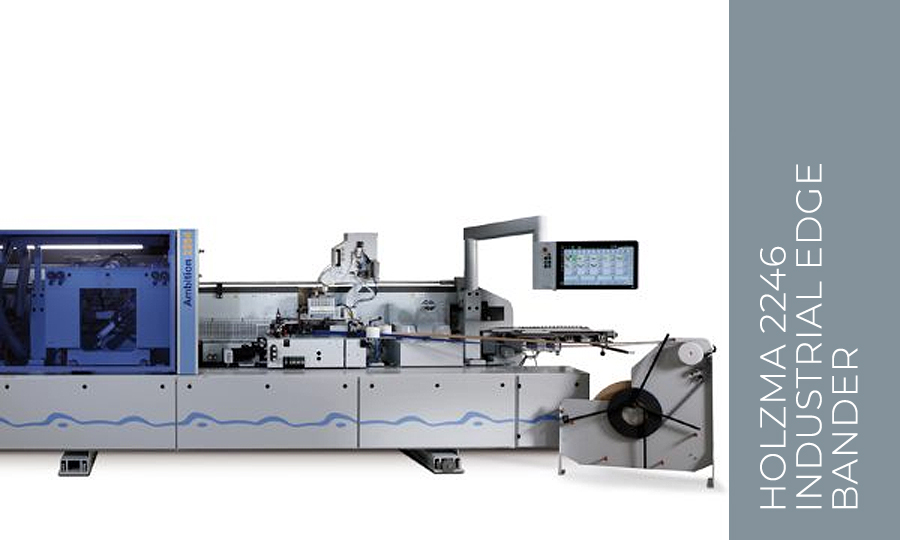

We have two German Homag edgebanders - an Ambition 2274 and Ambition 2264. These production machines can run at speeds of up to 25 metres a minute so larger volumes of edging are very welcome, while smaller runs can equally be accommodated as the machines are fully equipped to automatically change between tooling setups for different edge types.

We can offer PUR bonded edges.

What does this mean for you?

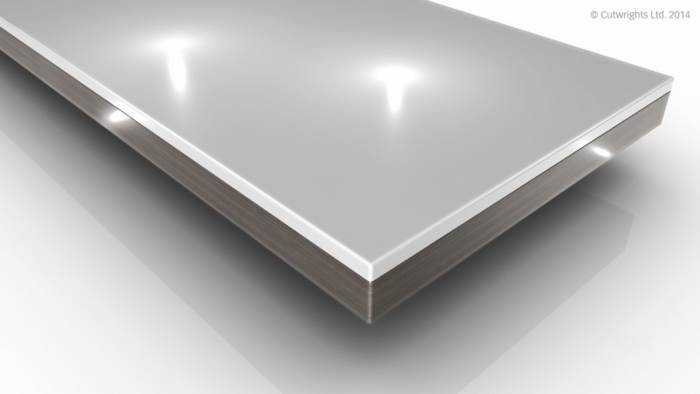

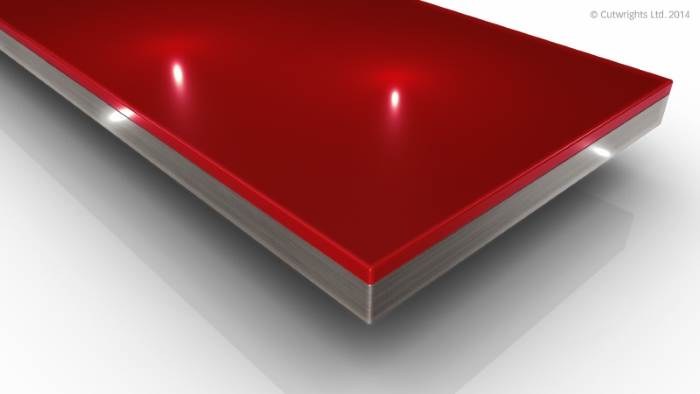

PUR (Polyurethane Reactive) glue edgbanding technology is the ultimate solution were high bond strength and moisture resistance are required. This high bond strength (chemical cross link) is maintained for panels that are to be used in wet or humid environments, where alternate systems would not be suitable. Another benefit of PUR is that you can achieve an almost invisible glue line.

How we achieve our finish?

Once a panel has entered the machine it passes a pre-milling station that trims the edge of the panel to ensure a clean crisp edge that's chip free, prior to the edging being applied. Then the soft touch finishing stations get to work, a typical panel will pass through around twelve stations in total. These stations are key to achieving an exceptional finish. Once the panel leaves the machine, there is no need for further manual finishing.

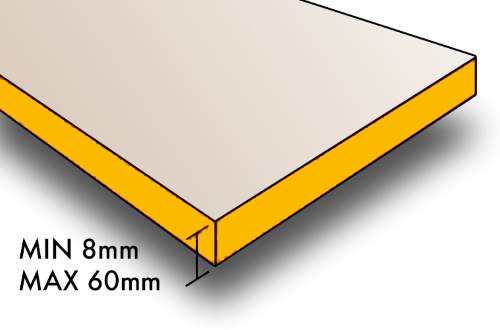

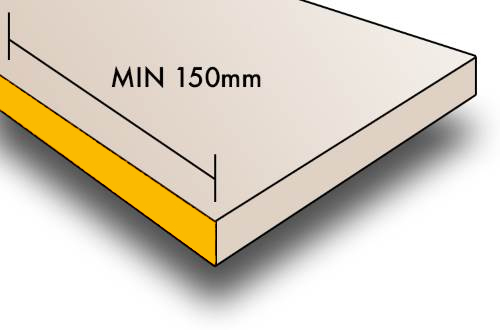

Machine capabilities explained

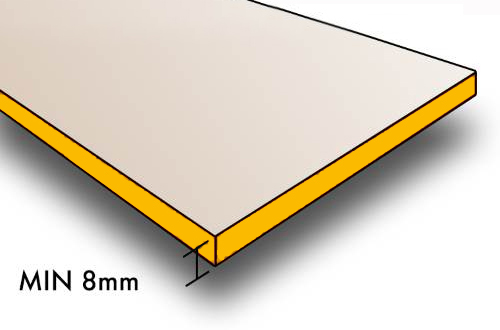

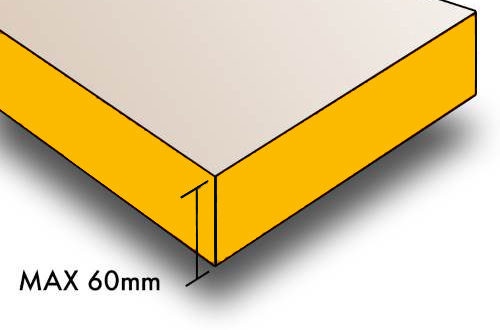

Minimum / Maximum thickness of panel that can be edged 8mm – 60mm

Minimum length of panel that can be edged without a recut 150mm

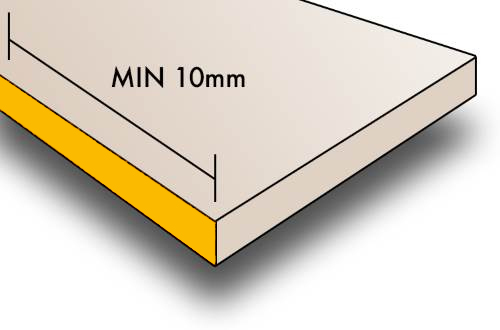

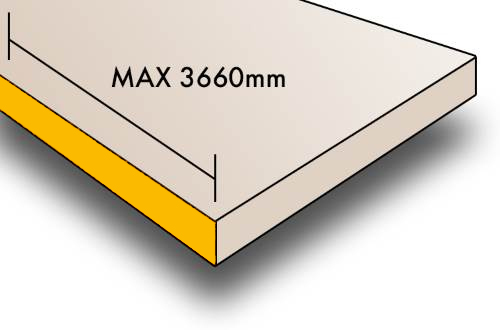

Minimum length of panel that can be egded with a recut 10mm

Maximum length of panel that can be edged 3660mm

Minimum thickness of panel we can corner round 8mm

Maximum thickness of panel we can corner round 60mm

Edging options explained

If you have edges that would be visible and require sanding we would recommend that you apply preparation tape it will give a professional finish and most importantly save valuable time not having to sand the edges that need to be painted. Edges finished in preparation tape can accept almost any paint or lacquer finish. It’s also great at preventing water penetration into the edges too. Available in two options, square and 2.0mm radius.

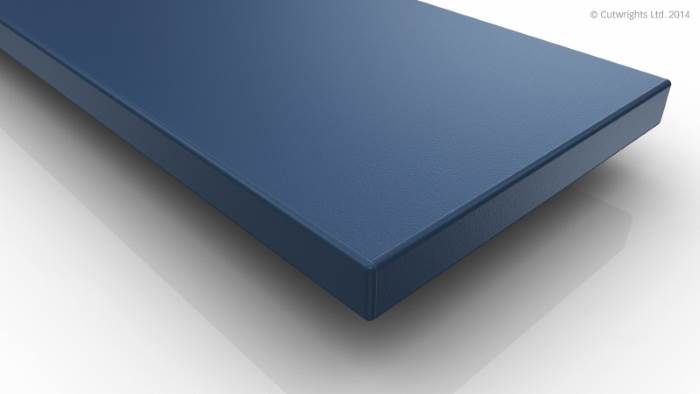

0.8mm & 1.0mm ABS is the new 2.0mm edging because of a trend toward seamless edges and the use of melamine faced panels being used for door frontals the 0.8mm & 1.0mm suit this application better as it shows less of the core plain colour of the edging which is particularly noticeable on wood grained boards.

By far the most commonly requested edge type we apply, mainly used for front edges of carcases, doors and desk top panels it offers a high impact protection. Panel edged with 2.0mm will have softer edges and corners due to the thickness of the edging and 2.0mm radius finish.

Used mostly with the Egger Eurolight lightweight panels with honeycomb substrates or bonded panels with chipboard / MDF substrates. Thicknesses vary in size up to and occasionally over 50mm thick. The Egger Eurolight boards are used to create chunky desk tops, shelves, and walk-in wardrobes and this edging finishes the panels perfectly.

3D Edge banding is made of transparent acrylic, which is printed or coated on the reverse side of the edging the advantage of this is that the print effect can never be marked once it is applied. The product also has outstanding impact and scratch resistance and looks great too.

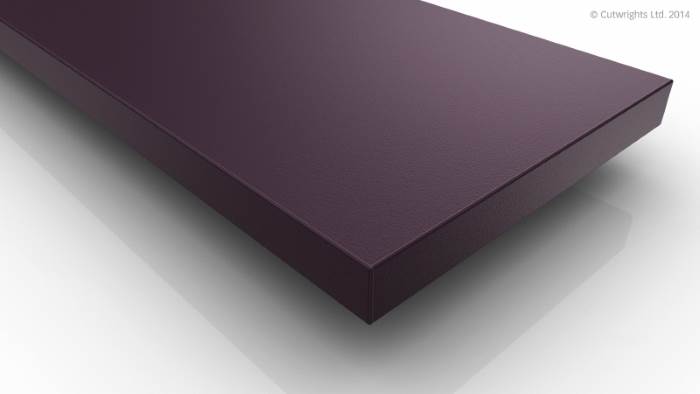

This edging is used with our range of acrylic faced boards and UV Lacquered range. More commonly used for edging panels that are being used for kitchens and wardrobes doors, it’s hard wearing.

A cost effective way of finishing real wood veneered panels giving a square edge due to the thickness but minimal impact durability.

Mainly used for front edges of carcases, shelves, doors and desk top panels it offers a high impact protection. Panels edged with 2.0mm will have softer edges and corners due to the thickness of the edging and radius finishing. (NB This edging is produced by laminating 4 x 0.5mm edges so we don’t advise the face of the edging to be overly sanded or planed down).