Understanding the types of MDF wood can help you select the best material for your project. From standard to moisture-resistant and fire-rated boards, each type offers unique properties suited to different applications. In this article, we’ll explore these varieties and guide you in choosing the right MDF for optimal results.

Key Takeaways

- Different types of MDF boards, including standard, ultra-light, fire-rated, moisture-resistant, formaldehyde-free, veneered, and laminated MDF, serve various specialised purposes, depending on factors like weight, fire safety, moisture exposure, and health considerations.

- Selecting the appropriate MDF type for a project involves considering specific requirements such as durability, performance, environmental conditions, and safety. This ensures optimal outcomes in construction, furniture making, cabinetry, and decorative elements.

- Working with MDF necessitates prioritising safety by using proper tools, ensuring ventilation, wearing protective gear, and following best practices for joining and finishing. This approach safeguards health and enhances the longevity and appearance of the finished products.

Understanding Medium Density Fibreboard (MDF)

Medium Density Fibreboard (MDF) is a synthetic product crafted from wood fibres, resin, and wax formed into flat panels, including medium-density fibreboards. Unlike particleboard, MDF boasts a more uniform density and smoother surface, making it ideal for various applications.

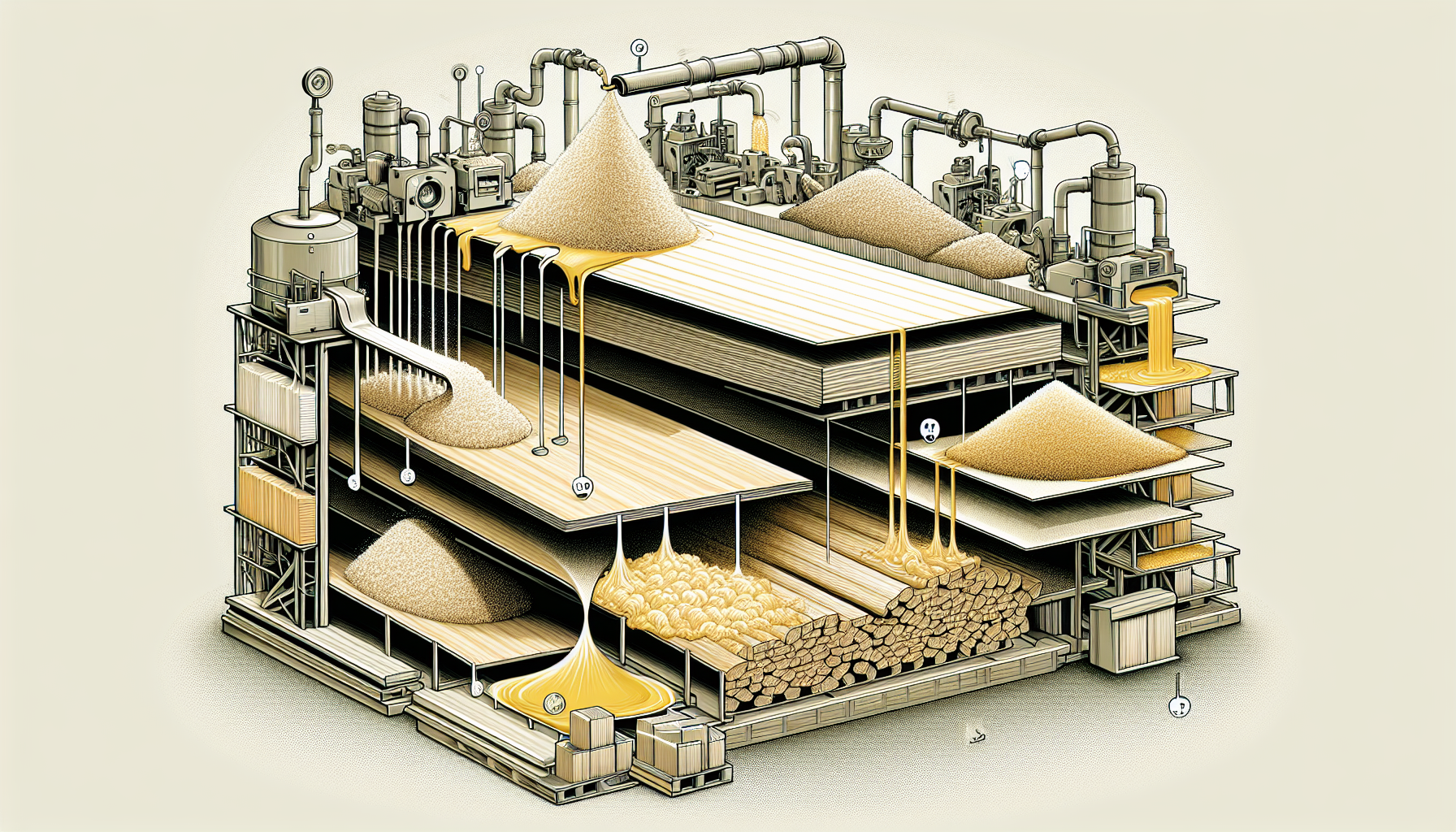

The process of creating MDF involves the following steps:

- Refining wood fibres using a defibrillator

- Mixing the wood fibres with resin and wax

- Compressing the mixture under high temperatures to form homogeneous boards

These steps result in the production of high-quality MDF boards.

One of the standout features of MDF is its density, which typically ranges between 660 and 850 kg/m³. This provides a stable and robust material that can be easily machined and finished. This consistency in density ensures that medium-density fibreboard products have smooth surfaces free from knots or grain patterns, making them perfect for detailed work and fine finishes.

The versatility of MDF makes it a popular choice for furniture projects and cabinetry, as well as the creation of veneered and laminated MDF. Its ability to form flat panels with uniform edges and surfaces means it can be used in applications where precision and smoothness are paramount. Whether you’re creating intricate furniture pieces or need a reliable material for cabinetry, MDF wood offers a reliable and cost-effective solution.

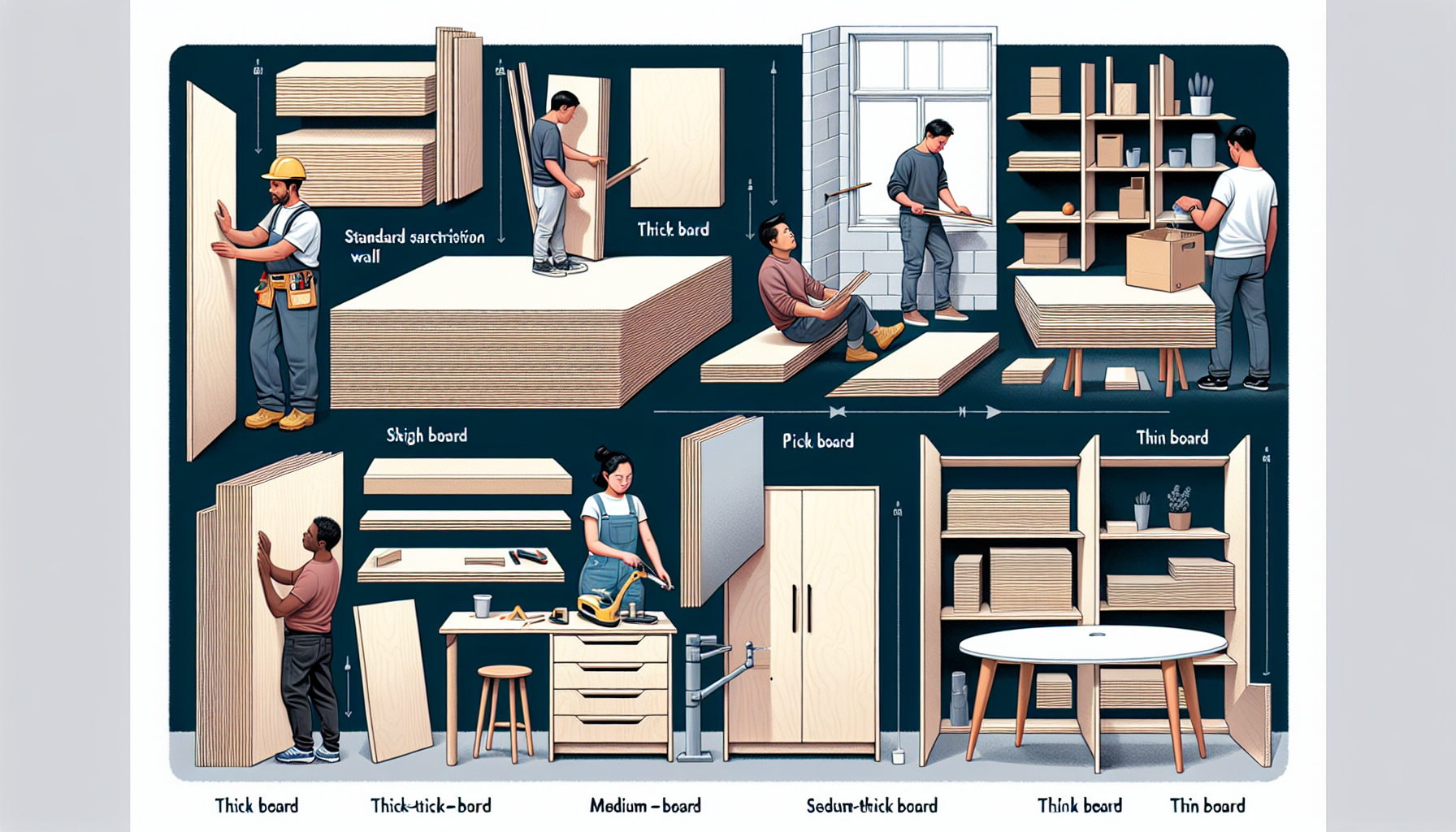

Standard MDF Boards

Standard MDF boards are the workhorses of the MDF family, offering a budget-friendly and versatile option for countless applications. These boards typically measure 244cm long by 122cm wide, with common thicknesses ranging from 3mm to 30mm, making them suitable for a variety of projects. Their homogeneous mix of wood fibres results in a uniform density that enhances edge and surface machining, which is crucial for automated furniture production.

Despite their many advantages, standard MDF boards are not without their drawbacks. They are heavy, stiff, and prone to chipping and scratching, which can be a consideration depending on the project’s demands. However, their high internal bond strength and dimensional stability make them ideal for furniture and cabinetry, where durability and precise machining are essential. The density of standard MDF is controlled to ensure good strength and durability, often measured in kg/m³.

In addition to their mechanical properties, standard MDF boards have the following features:

- They hold screws well and have good screw-holding strengths, typically around 1000N in the face and 700 to 950N in the edge.

- This makes them reliable for constructing cabinets, shelves, and other load-bearing surfaces where strength and stability are paramount.

- With the right finishing techniques, these boards can deliver high-quality results for a range of furniture projects.

Ultra-Light MDF Boards

For projects where weight is a critical factor, ultra-light MDF boards offer a practical solution. These boards are about 30% lighter than standard MDF, making them significantly more straightforward to handle and work with. This weight reduction not only simplifies transportation but also eases the manipulation of materials during the construction process.

Ultra-light MDF boards maintain a smooth, high-quality surface that is ideal for furniture making and other detailed applications. Their lightweight nature makes them particularly suitable for projects where minimising weight is essential, such as in certain types of furniture or decorative elements. Despite being lighter, they still offer many of the benefits of regular MDF, including ease of finishing and stability.

Fire-Rated MDF Boards

Safety is paramount in environments like schools, hospitals, and offices, where fire-rated MDF boards can be particularly beneficial. These boards are designed to slow the spread of fire for up to 30 minutes, earning them a Euroclass C Fire Rating. The fire retardant treatment embedded in the boards provides inherent fire resistance, although any cuts or drilling can affect the fire rating at those spots.

Fire-rated MDF boards are easily identifiable by their red or blue markings, indicating their special fire-resistant properties. These boards are suitable for use in areas prone to wildfires or near heat sources, such as:

- cabinetry built near stoves or ovens

- wall linings

- partitions

- display panels in high-risk environments

Sheet material is not only cost-effective but also adaptable for these applications.

However, it’s important to consider that while fire-rated MDF offers significant safety benefits, the integrity of its fire resistance can be compromised by improper handling and installation. Ensuring that these boards are used and maintained correctly is crucial to maximising their effectiveness in fire protection.

Moisture-Resistant MDF Boards

In environments prone to humidity and moisture, such as bathrooms and kitchens, moisture-resistant MDF boards are an excellent choice. These boards are treated with wax to enhance their resistance to humidity and moisture, making them durable in wet conditions. While they are not solid wood, they share similar characteristics in terms of durability and workability.

Identifiable by the green stamps on their edges, moisture-resistant MDF boards are particularly suitable for humid environments where regular MDF would fail. Their enhanced moisture resistance makes them ideal for cabinetry, flooring, and other applications in areas that frequently encounter wet conditions.

Formaldehyde-Free MDF Boards

Health and safety are significant considerations when selecting materials for interior applications, and formaldehyde-free MDF boards offer a safer alternative. MDF typically contains urea-formaldehyde, a known carcinogen that can cause respiratory issues and skin irritation. Formaldehyde-free MDF boards reduce these health risks by eliminating this harmful compound, providing a safer living environment.

Choosing formaldehyde-free MDF has several benefits:

- It significantly improves indoor air quality, making it ideal for homes with children or individuals with respiratory conditions.

- It aligns with sustainable manufacturing practices, supporting a healthier planet.

- It contributes to long-term health benefits. By opting for these safer alternatives, you can ensure that your projects are both environmentally friendly and health-conscious.

Veneered MDF Boards

Veneered MDF boards, also known as veneered boards, combine the best of both worlds by attaching high-quality wood veneers to medium-density fibreboards. This combination offers the aesthetic appeal of solid wood with the stability and cost-effectiveness of MDF. The smooth surface of veneered MDF makes it suitable for a variety of furniture and decorative applications, providing a reliable alternative to solid wood at a fraction of the cost.

These boards are particularly stable and less susceptible to fluctuations in humidity and heat compared to solid wood. Veneered MDF is ideal for internal applications such as office furniture, kitchen cabinets, and dining sets, where both appearance and performance are important. The ease of customisation, sanding, and marking makes veneered MDF a favourite among furniture makers and interior designers.

In addition to their practical benefits, veneered MDF boards also offer a sustainable alternative:

- Utilising wood shavings and other materials that might otherwise go to waste

- Reducing costs

- Supporting environmentally friendly practices in furniture making and construction.

Laminated MDF Boards

Laminated MDF boards are known for their durability and scratch-resistant surfaces, making them ideal for high-use areas such as cupboards and tabletops. These boards can mimic the appearance of solid wood while providing a more robust and easy-to-maintain surface.

The smooth, laminated surface of these MDF boards makes them easy to clean and maintain, which is especially beneficial in settings where hygiene is crucial. Their practical applications extend to various types of furniture and cabinetry, offering a cost-effective and durable solution for high-traffic areas.

Selecting the Right Type of MDF for Your Project

Choosing the correct type of MDF for your project depends on several factors, including durability, performance, and environmental conditions. For general purposes, standard MDF is versatile and affordable, making it suitable for a wide range of applications such as construction, furniture, and cabinetry. If weight is a concern, ultra-light MDF boards are ideal for projects where handling and transportation are critical.

In environments requiring extra fire protection, fire-rated MDF boards provide the necessary safety features, making them suitable for schools, hospitals, and other high-risk areas. For humid conditions, moisture-resistant MDF boards are the best option, ensuring durability and performance in bathrooms and kitchens. Lastly, for health-conscious projects, formaldehyde-free MDF boards offer a safer alternative, improving indoor air quality and reducing health risks.

By considering these factors and your project's specific requirements, you can select the MDF type that ensures the best durability and performance. Whether you’re building furniture, cabinetry, or decorative elements, there’s an MDF board tailored to meet your needs.

Working with MDF

When working with MDF, safety should always be a top priority. Here are some safety tips to keep in mind:

- Use tools with low grit content to reduce the wear on cutting tools caused by abrasive particles in MDF.

- Proper ventilation is important to prevent the inhalation of fine dust produced by MDF. Consider working outdoors or in a well-ventilated area.

- Wear a facemask and goggles to protect against the health risks associated with MDF dust.

- Consider wearing a respirator to further protect against exposure to resins and fine dust.

When joining MDF panels, it’s important to consider that screws may not be as effective as they are with plywood. This is because of the nature of the MDF material. Furniture cam locks and carpenter’s glue are reliable alternatives for creating strong joints. Ensuring effective dust extraction systems, such as local exhaust ventilation (LEV), and using high-performance filters (HEPA) in vacuum cleaners can significantly reduce dust exposure.

Respiratory protective equipment (RPE) should complement other control measures, such as dust extraction systems, rather than being the sole means of protection. RPE, like a face filtering piece (FFP) or a half-mask with a P3 particle filter, can provide additional protection against wood dust. By following these safety precautions and best practices, you can work with MDF efficiently and safely.

Finishing MDF Boards

Achieving a professional finish on MDF boards involves several key steps:

- Sand the MDF with 120-grit sandpaper and then with 220 grit to create a smooth, uniform surface.

- Safety glasses or a full face shield to protect your vision

- Use a lint-free tack cloth to remove fine dust particles before painting.

- Patch small holes or cracks with wood filler compound to ensure an even surface before applying primer.

Priming is crucial when finishing MDF. Here are the steps to follow:

- Apply two coats of an oil-based or shellac primer to create a smooth base for painting and to prevent uneven paint absorption.

- The first thin coat of paint acts as a sealant, and using acrylic enamel paints will provide optimal adhesion and durability.

- For final protection, seal painted MDF surfaces with an oil-based polyurethane, ensuring a long-lasting finish.

Proper finishing techniques not only enhance the appearance of MDF but also protect it from moisture and damage. By following these steps, you can achieve a high-quality, professional finish that will stand the test of time.

Summary

Navigating the world of MDF can seem daunting, but understanding the different types and their applications can make all the difference. From standard and ultra-light MDF to fire-rated and moisture-resistant options, each type offers unique benefits tailored to specific needs. Selecting the right MDF type ensures durability, performance, and safety in your projects.

By considering factors such as weight, fire resistance, moisture resistance, and health impacts, you can make informed decisions that enhance the quality and longevity of your work. Investing in the right MDF board not only improves the aesthetic and functional aspects of your projects but also contributes to a healthier and safer environment.

Frequently Asked Questions

Q: What is the difference between MDF and particleboard?

A: MDF has a more uniform density and smoother surface compared to particleboard, making it better for detailed work and fine finishes.

Q: Can MDF be used in humid environments?

A: Yes, moisture-resistant MDF boards are treated to resist humidity and moisture, making them suitable for use in humid environments.

Q: Are there health concerns when working with MDF?

A: Yes, there are health concerns when working with MDF due to the presence of urea-formaldehyde, which can lead to respiratory issues if proper safety precautions are not taken. Using formaldehyde-free MDF and wearing appropriate safety gear can help reduce these risks.

Q: How can I achieve a professional finish on MDF?

A: To achieve a professional finish on MDF, sand it, apply primer, paint with acrylic enamel, and seal with an oil-based polyurethane for a smooth and durable result.

Q: What are the benefits of ultra-light MDF boards?

A: Ultra-light MDF boards are approximately 30% lighter than standard MDF, making them easier to handle and ideal for projects where weight reduction is crucial. This makes them a great choice for various applications.