Cutting MDF requires the right tools and techniques. This guide will show you how to cut MDF using circular saws, jigsaws, and table saws, and it will cover essential safety tips.

Key Takeaways

- MDF (Medium Density Fibreboard) is a popular material in woodworking due to its smooth, consistent surface and affordability, but it is prone to damage from moisture.

- Effective MDF cutting requires specific tools such as a circular saw, jigsaw, and table saw, each with the appropriate blade type and settings to ensure clean, precise cuts.

- Safety measures are critical when cutting MDF due to the fine dust it produces, which contains harmful substances like formaldehyde. Proper protective gear and maintaining good ventilation are essential to protect health.

Understanding MDF: The Basics

At first glance, MDF might seem like any other building material, but it’s so much more. Medium-density fibreboard, or MDF, is the darling of the woodworking world, cherished for its affordability and smooth, knot-free surface. Crafted from a mix of wood fibres and adhesive and subjected to high pressure and heat, MDF sheets are the go-to choice for consistent, quality finishes. Envision creating furniture or cabinetry with an MDF board, a uniform surface that must be painted or varnished to perfection.

However, as with all materials, MDF has its kryptonite - moisture. Exposure to the elements can cause swelling, warping, or even deterioration, making it less ideal for places where humidity reigns supreme. But don’t fret; for every limitation, there’s a workaround. Fire-retardant MDF exists for those high-stakes environments, ensuring durability and safety where it matters most

Essential Tools for Cutting MDF

Equipping yourself with the right tools is like arming a knight for battle. When it comes to cutting MDF, the choice of your arsenal can make or break the outcome of your project. A fine-tooth blade is your trusty steed, leading to accurate and clean cuts across various MDF panels. But the journey doesn’t end here. When using a jigsaw, ensure the bi-metal cutting blade is securely placed in the device's blade clamp mechanism for optimal performance.

Let’s delve into the specifics of the trusty circular saw, the versatile jigsaw and the robust table saw, each pivotal in cutting MDF with finesse.

Circular Saw

The circular saw is a popular choice among woodworkers because of its precision and ease of use. To wield this tool like a pro, opt for a blade with a 60-teeth count, a width of around 14 inches, and a carbide tip. These specifications ensure your cuts are as clean and straight as an arrow, minimising chipping and tear-out in your MDF sheets.

Set your trusty circular saw to a brisk cutting speed of around 3,000 metres per second, keeping within the 6000 to 8000 RPM range. Watch as it glides through MDF like butter, leaving behind a trail of precise cuts.

Jigsaw

For those moments when your design calls for a touch of whimsy or complexity, the jigsaw steps into the limelight. It’s your go-to tool for creating curved cuts that would make a snake envious, and it can navigate tight spaces with the agility of a cat.

A bi-metal cutting blade is the jigsaw’s best companion, ensuring intricate and clean cuts. Remember to secure the narrow blade firmly within the device’s blade clamp mechanism, taking care to disconnect the power source first. As you guide the jigsaw blade along your marked masterpiece, maintain a slow and steady pace, allowing the tool to do the intricate dance, resulting in cuts that are as precise as a finely tuned orchestra.

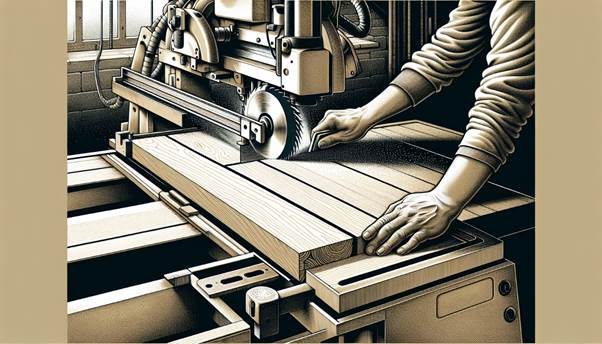

Table Saw

The table saw stands as your guardian when straight cuts are your bread and butter. It’s the cornerstone of MDF cutting, ensuring edges are as sharp and clean as a well-tailored suit. Arm your table saw with a carbide-tipped blade that champions endurance and precision.

The secret to a perfect cut lies in the feed rate – a steady, moderate pace will avoid the dreaded rough edges and inaccuracies, leaving you with MDF sheets cut to perfection.

Safety Precautions When Cutting MDF

Venturing into the world of MDF cutting without proper protection is akin to stepping into a storm without an umbrella. The fine dust produced during cutting, laced with formaldehyde, is not something to take lightly. To guard against long-term health risks, protect yourself with gloves, goggles, and a dust mask approved for dust and formaldehyde. Moreover, the dust from MDF has been linked to serious conditions such as nasal and sinus cancer, not to mention asthma and chronic bronchitis.

Ventilation is your ally in this battle against harmful particles. Cutting MDF in a well-ventilated area or using dust extraction tools preserves your health and ensures a cleaner working environment. Safety is not an afterthought – it’s a cornerstone of craftsmanship. Don the right protective gear and make your health a priority every time you set out to cut MDF.

Techniques for Accurate Cuts

Precision is the hallmark of a true craftsman, and cutting MDF is no exception. Selecting the right technique is as crucial as choosing the perfect tool. From scoring the cut line to ensure a chip-free edge to supporting and clamping the workpiece for stability to adjusting blade height and feed rate for the ultimate cut – each step is a dance, a meticulous choreography that leads to the crescendo of a flawless finish.

Scoring the Cut Line

Imagine drawing a line in the sand with a straight edge. This is what scoring the cut line in MDF is like. But instead of a stick, you have a utility knife, a tool that guides the saw blade.

Mark your line with a pencil, validate it with a tape measure, and then let the knife dance across the MDF’s surface, making multiple passes if necessary. This simple act of scoring creates a path that minimises chipping and tear-out, ensuring that the edges of your MDF plank emerge as smooth as glass.

Supporting and Clamping the Workpiece

The last thing you want is for your MDF panel to wobble like a jelly on a plate mid-cut. To prevent such a scenario, ensure that your MDF plank is firmly anchored to your workbench, with any overhanging sections supported by bench dogs or other clamping mechanisms.

Heavy-duty clamps around the plank’s borders act like a steadfast embrace, keeping the MDF perfectly still as you make your incisions. This makes for a safer cutting environment and results in cuts that are so accurate they would make a mathematician proud.

Adjusting Blade Height and Feed Rate

Adjusting the blade height is like tuning an instrument – get it right, and the results are harmonious. Set your saw blade to peek just a tad above the MDF’s thickness, neither too shy nor too bold, for that perfect cut.

And then there’s the feed rate – the rhythm of your cutting symphony. Too fast, and the blade protests with burn marks; too slow, and it may bind. Find that steady tempo that allows the blade to sing through the MDF, leaving a smooth, unblemished surface behind.

Treating and Finishing MDF Edge

After the cutting comes the finishing – a task that transforms a raw MDF edge into a polished, presentable feature. This is where sanding and sealing come into play, smoothing out the roughness and preparing the surface for a coat of paint or other finishings.

And for those edges that need extra protection, edge banding offers a shield against moisture and wear, ensuring your project stands the test of time.

Sanding and Sealing Edges

The edges of MDF can be as rough as a pirate’s language after a cut, but a little sanding can make them as smooth as a diplomat’s speech. Start with a 220-grit sandpaper, and work your way up to a finer 320-grit for a surface that’s ready to embrace a sealer.

Select a shellac-based primer, such as Zinsser BIN. This primer not only seals those thirsty edges but also provides an ideal base for waterborne lacquer, ensuring a finish that’s both durable and visually striking

Applying Edge Banding

Edge banding is like armour for your MDF edges—it protects against the slings and arrows of everyday use. Using an edge bander, apply paintable melamine edge banding for a seamless look that requires no further sealing and is ready to receive whatever colour your heart desires.

Remember, protecting your MDF edges enhances your project's appearance and extends its lifespan, ensuring your hard work pays off for years to come.

Advanced Cutting Methods

Once you’ve mastered the basics, you might crave more intricate and precise cuts that turn heads and start conversations. This is where advanced cutting methods come into play. Laser-cutting machines offer the precision of a surgeon, slicing through MDF to create complex patterns and shapes with ease.

CNC routers are the tool of choice for those seeking the ability to carve elaborate designs, transforming a simple MDF sheet into a work of art.

Financial Benefits of Using Cutwrights' MDF Cutting Service

Cutting your own MDF can be satisfying, but when precision and efficiency matter, it pays to call in the professionals. Cutwrights’ MDF cutting service is a game-changer. It reduces material waste and ensures every cut is precise, minimising the costly errors that can haunt the uninitiated.

Not only do you save on the hefty investment of tools and machinery, but your operational efficiency skyrockets, allowing you to focus on design and assembly rather than the nitty-gritty of the cutting process. Plus, with faster project turnaround, you’ll see customer satisfaction soar, proving that sometimes, the best cut is the one you leave to the experts.

Expert Tips from Robin Clevett

When a master craftsman like Robin Clevett offers wisdom, it’s wise to listen. Cutting MDF demands precision; according to Robin, the blade makes all the difference. A sharp blade is key to clean, precise cuts, and a high-tooth count blade minimises the pesky chipping that can mar your work.

He also advocates for using the right techniques, like scoring the cut line, a simple step that can elevate your MDF cutting game to new heights.

Summary

From selecting the right tools and blades to understanding the nuances of scoring and supporting your workpiece, cutting MDF is both an art and a science. By following the guidance of experts, embracing safety precautions, and treating your edges with care, you can transform a humble MDF board into a masterpiece. Whether you do it yourself or opt for the efficiency of a professional cutting service, the path to MDF mastery is now within your grasp.

Frequently Asked Questions

Q: What is the best saw blade for cutting MDF?

A: The best saw blade for cutting MDF is a fine-tooth blade designed for wood composites or melamine-coated materials. It should have a high tooth count and a carbide tip, which will ensure clean and precise cuts.

Q: How can I prevent my MDF from chipping when I cut it?

A: To prevent chipping when cutting MDF, score the cut line with a utility knife before sawing to create a guide for the blade. This will help minimise chipping and tear-out.

Q: Is it safe to cut MDF without wearing a mask?

A: No, it's not safe to cut MDF without wearing a mask. Protect against harmful particles and gases by wearing protective gear, including a dust mask or respirator, goggles, and gloves

Q: Can I use a jigsaw for straight cuts on MDF?

A: Yes, you can use a jigsaw for straight cuts on MDF, but a table or circular saw is recommended for the cleanest and most precise cuts.

Q: What are the benefits of using Cutwrights' MDF cutting service?

A: Using Cutwrights' MDF cutting service can save you time and money by reducing material waste, avoiding errors, ensuring faster project completion times, and enhancing operational efficiency and customer satisfaction.